Introduction to Waterborne Calcium Stearate

Waterborne calcium stearate has become a critical product in modern commercial applications as a result of its eco-friendly account and multifunctional capabilities. Unlike traditional solvent-based ingredients, waterborne calcium stearate offers a lasting choice that meets expanding demands for low-VOC (unpredictable organic substance) and safe solutions. As regulatory stress places on chemical use across markets, this water-based diffusion of calcium stearate is getting grip in coatings, plastics, construction products, and much more.

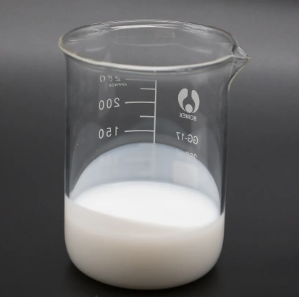

(Parameters of Calcium Stearate Emulsion)

Chemical Structure and Physical Characteristic

Calcium stearate is a calcium salt of stearic acid with the molecular formula Ca(C āā H āā O ā)TWO. In its traditional type, it is a white, waxy powder understood for its lubricating, water-repellent, and maintaining buildings. Waterborne calcium stearate refers to a colloidal diffusion of great calcium stearate fragments in a liquid medium, typically maintained by surfactants or dispersants to stop cluster. This formulation enables simple consolidation into water-based systems without compromising performance. Its high melting point (> 200 Ā° C), low solubility in water, and excellent compatibility with different materials make it optimal for a large range of useful and structural functions.

Manufacturing Process and Technological Advancements

The production of waterborne calcium stearate normally includes neutralizing stearic acid with calcium hydroxide under regulated temperature and pH conditions to form calcium stearate soap, followed by dispersion in water using high-shear mixing and stabilizers. Recent growths have actually concentrated on improving particle dimension control, increasing solid web content, and lessening environmental influence with greener handling techniques. Technologies such as ultrasonic-assisted emulsification and microfluidization are being discovered to improve dispersion security and functional efficiency, making certain constant quality and scalability for commercial users.

Applications in Coatings and Paints

In the finishings market, waterborne calcium stearate plays a vital function as a matting representative, anti-settling additive, and rheology modifier. It helps reduce surface area gloss while maintaining film stability, making it particularly useful in building paints, wood finishings, and commercial surfaces. Additionally, it enhances pigment suspension and protects against drooping during application. Its hydrophobic nature likewise enhances water resistance and toughness, adding to longer layer lifespan and minimized maintenance costs. With the shift toward water-based coverings driven by ecological guidelines, waterborne calcium stearate is becoming a necessary solution element.

( TRUNNANO Calcium Stearate Emulsion)

Duty in Plastics and Polymer Handling

In polymer manufacturing, waterborne calcium stearate offers mainly as an internal and outside lubricating substance. It promotes smooth melt flow during extrusion and shot molding, minimizing die build-up and improving surface area finish. As a stabilizer, it reduces the effects of acidic residues created during PVC handling, avoiding deterioration and discoloration. Compared to typical powdered types, the waterborne variation supplies far better dispersion within the polymer matrix, causing improved mechanical residential or commercial properties and procedure efficiency. This makes it particularly valuable in rigid PVC accounts, cords, and films where appearance and efficiency are extremely important.

Use in Construction and Cementitious Systems

Waterborne calcium stearate finds application in the construction market as a water-repellent admixture for concrete, mortar, and plaster products. When integrated into cementitious systems, it forms a hydrophobic obstacle within the pore framework, substantially decreasing water absorption and capillary surge. This not just enhances freeze-thaw resistance however also shields versus chloride ingress and deterioration of embedded steel reinforcements. Its ease of combination into ready-mix concrete and dry-mix mortars positions it as a recommended solution for waterproofing in infrastructure projects, passages, and below ground frameworks.

Environmental and Health And Wellness Considerations

Among the most compelling advantages of waterborne calcium stearate is its environmental profile. Free from volatile natural substances (VOCs) and hazardous air pollutants (HAPs), it aligns with global initiatives to reduce commercial exhausts and advertise environment-friendly chemistry. Its biodegradable nature and low toxicity additional support its fostering in environmentally friendly line of product. However, appropriate handling and formulation are still called for to guarantee worker safety and security and prevent dirt generation throughout storage space and transport. Life process assessments (LCAs) significantly favor such water-based additives over their solvent-borne equivalents, enhancing their function in lasting manufacturing.

Market Trends and Future Expectation

Driven by stricter environmental regulations and increasing customer recognition, the market for waterborne ingredients like calcium stearate is increasing quickly. The Asia-Pacific area, in particular, is experiencing strong growth because of urbanization and industrialization in countries such as China and India. Principal are investing in R&D to establish customized grades with improved functionality, consisting of warm resistance, faster diffusion, and compatibility with bio-based polymers. The integration of digital technologies, such as real-time tracking and AI-driven formulation tools, is expected to further maximize performance and cost-efficiency.

Final thought: A Lasting Building Block for Tomorrow’s Industries

Waterborne calcium stearate stands for a substantial improvement in practical products, using a well balanced mix of performance and sustainability. From coatings and polymers to construction and beyond, its adaptability is improving how markets approach solution style and process optimization. As business strive to meet developing regulatory requirements and customer expectations, waterborne calcium stearate stands apart as a dependable, adaptable, and future-ready solution. With continuous innovation and much deeper cross-sector partnership, it is positioned to play an also better role in the change toward greener and smarter making practices.

Vendor

Cabr-Concrete is a supplier under TRUNNANO of Concrete Admixture with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for Concrete foaming agent, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com)

Tags: calcium stearate,ca stearate,calcium stearate chemical formula

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us