1. Product Basics and Structural Features of Alumina Ceramics

1.1 Crystallographic and Compositional Basis of α-Alumina

(Alumina Ceramic Substrates)

Alumina ceramic substratums, mostly made up of light weight aluminum oxide (Al two O TWO), function as the foundation of modern-day electronic product packaging due to their phenomenal equilibrium of electric insulation, thermal stability, mechanical toughness, and manufacturability.

The most thermodynamically steady stage of alumina at high temperatures is corundum, or α-Al â O FIVE, which crystallizes in a hexagonal close-packed oxygen lattice with aluminum ions occupying two-thirds of the octahedral interstitial websites.

This thick atomic plan imparts high hardness (Mohs 9), outstanding wear resistance, and strong chemical inertness, making α-alumina ideal for rough operating settings.

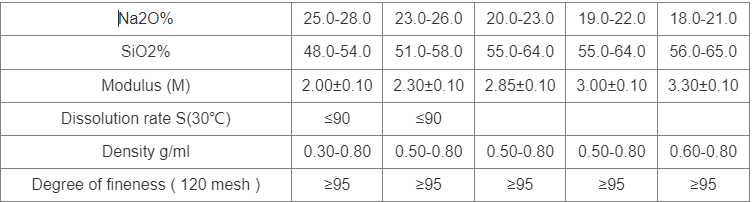

Commercial substratums usually include 90– 99.8% Al â O TWO, with minor enhancements of silica (SiO TWO), magnesia (MgO), or rare planet oxides used as sintering aids to advertise densification and control grain growth throughout high-temperature handling.

Higher pureness grades (e.g., 99.5% and over) exhibit superior electrical resistivity and thermal conductivity, while lower purity variations (90– 96%) supply affordable remedies for less requiring applications.

1.2 Microstructure and Defect Engineering for Electronic Integrity

The efficiency of alumina substratums in electronic systems is seriously depending on microstructural uniformity and issue minimization.

A fine, equiaxed grain structure– commonly ranging from 1 to 10 micrometers– ensures mechanical stability and minimizes the possibility of split proliferation under thermal or mechanical anxiety.

Porosity, specifically interconnected or surface-connected pores, have to be lessened as it degrades both mechanical toughness and dielectric performance.

Advanced handling techniques such as tape casting, isostatic pressing, and controlled sintering in air or regulated atmospheres allow the manufacturing of substrates with near-theoretical density (> 99.5%) and surface roughness listed below 0.5 ”m, essential for thin-film metallization and cord bonding.

In addition, impurity segregation at grain limits can lead to leak currents or electrochemical migration under prejudice, demanding strict control over resources pureness and sintering problems to make certain long-lasting dependability in humid or high-voltage settings.

2. Production Processes and Substrate Manufacture Technologies

( Alumina Ceramic Substrates)

2.1 Tape Spreading and Environment-friendly Body Handling

The production of alumina ceramic substrates begins with the preparation of an extremely dispersed slurry including submicron Al â O â powder, organic binders, plasticizers, dispersants, and solvents.

This slurry is refined using tape spreading– a constant approach where the suspension is spread over a moving provider movie using an accuracy medical professional blade to accomplish uniform density, usually between 0.1 mm and 1.0 mm.

After solvent evaporation, the resulting “green tape” is versatile and can be punched, pierced, or laser-cut to develop by means of openings for vertical affiliations.

Numerous layers might be laminated to create multilayer substrates for complex circuit integration, although the majority of industrial applications utilize single-layer configurations because of set you back and thermal development considerations.

The green tapes are after that very carefully debound to get rid of natural additives through regulated thermal decomposition prior to last sintering.

2.2 Sintering and Metallization for Circuit Combination

Sintering is performed in air at temperatures between 1550 ° C and 1650 ° C, where solid-state diffusion drives pore removal and grain coarsening to achieve complete densification.

The direct contraction throughout sintering– usually 15– 20%– have to be exactly forecasted and made up for in the design of green tapes to make sure dimensional accuracy of the final substratum.

Complying with sintering, metallization is put on develop conductive traces, pads, and vias.

Two key approaches control: thick-film printing and thin-film deposition.

In thick-film innovation, pastes consisting of metal powders (e.g., tungsten, molybdenum, or silver-palladium alloys) are screen-printed onto the substrate and co-fired in a minimizing atmosphere to create robust, high-adhesion conductors.

For high-density or high-frequency applications, thin-film procedures such as sputtering or dissipation are made use of to deposit adhesion layers (e.g., titanium or chromium) followed by copper or gold, making it possible for sub-micron patterning by means of photolithography.

Vias are full of conductive pastes and fired to establish electrical interconnections in between layers in multilayer designs.

3. Useful Features and Performance Metrics in Electronic Equipment

3.1 Thermal and Electrical Actions Under Functional Tension

Alumina substratums are prized for their beneficial mix of modest thermal conductivity (20– 35 W/m · K for 96– 99.8% Al Two O SIX), which makes it possible for efficient heat dissipation from power gadgets, and high quantity resistivity (> 10 Âč⎠Ω · cm), guaranteeing very little leak current.

Their dielectric constant (Δᔣ â 9– 10 at 1 MHz) is stable over a vast temperature level and regularity array, making them ideal for high-frequency circuits approximately several gigahertz, although lower-Îș products like aluminum nitride are liked for mm-wave applications.

The coefficient of thermal development (CTE) of alumina (~ 6.8– 7.2 ppm/K) is reasonably well-matched to that of silicon (~ 3 ppm/K) and specific packaging alloys, lowering thermo-mechanical tension throughout tool operation and thermal biking.

However, the CTE mismatch with silicon remains an issue in flip-chip and direct die-attach configurations, typically requiring certified interposers or underfill materials to alleviate fatigue failing.

3.2 Mechanical Toughness and Ecological Toughness

Mechanically, alumina substrates display high flexural strength (300– 400 MPa) and outstanding dimensional security under load, allowing their usage in ruggedized electronics for aerospace, vehicle, and commercial control systems.

They are immune to vibration, shock, and creep at raised temperature levels, keeping structural integrity approximately 1500 ° C in inert environments.

In humid environments, high-purity alumina reveals very little wetness absorption and excellent resistance to ion migration, making sure long-lasting integrity in exterior and high-humidity applications.

Surface hardness likewise shields versus mechanical damages during handling and setting up, although care must be taken to avoid side breaking as a result of integral brittleness.

4. Industrial Applications and Technological Impact Across Sectors

4.1 Power Electronics, RF Modules, and Automotive Solutions

Alumina ceramic substratums are common in power digital components, consisting of insulated gate bipolar transistors (IGBTs), MOSFETs, and rectifiers, where they provide electrical seclusion while promoting warmth transfer to heat sinks.

In superhigh frequency (RF) and microwave circuits, they function as carrier platforms for hybrid integrated circuits (HICs), surface acoustic wave (SAW) filters, and antenna feed networks due to their steady dielectric buildings and low loss tangent.

In the vehicle sector, alumina substrates are used in engine control devices (ECUs), sensor packages, and electrical automobile (EV) power converters, where they endure high temperatures, thermal biking, and exposure to destructive fluids.

Their reliability under extreme problems makes them essential for safety-critical systems such as anti-lock braking (ABS) and advanced chauffeur support systems (ADAS).

4.2 Medical Gadgets, Aerospace, and Arising Micro-Electro-Mechanical Solutions

Beyond customer and industrial electronics, alumina substrates are utilized in implantable clinical tools such as pacemakers and neurostimulators, where hermetic securing and biocompatibility are critical.

In aerospace and protection, they are utilized in avionics, radar systems, and satellite interaction components because of their radiation resistance and security in vacuum settings.

In addition, alumina is significantly utilized as a structural and protecting platform in micro-electro-mechanical systems (MEMS), including stress sensors, accelerometers, and microfluidic devices, where its chemical inertness and compatibility with thin-film processing are advantageous.

As digital systems remain to demand greater power thickness, miniaturization, and dependability under severe conditions, alumina ceramic substrates remain a keystone product, linking the void in between efficiency, price, and manufacturability in sophisticated electronic packaging.

5. Vendor

Alumina Technology Co., Ltd focus on the research and development, production and sales of aluminum oxide powder, aluminum oxide products, aluminum oxide crucible, etc., serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services. If you are looking for high quality zirconia toughened alumina ceramics, please feel free to contact us. (nanotrun@yahoo.com)

Tags: Alumina Ceramic Substrates, Alumina Ceramics, alumina

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us